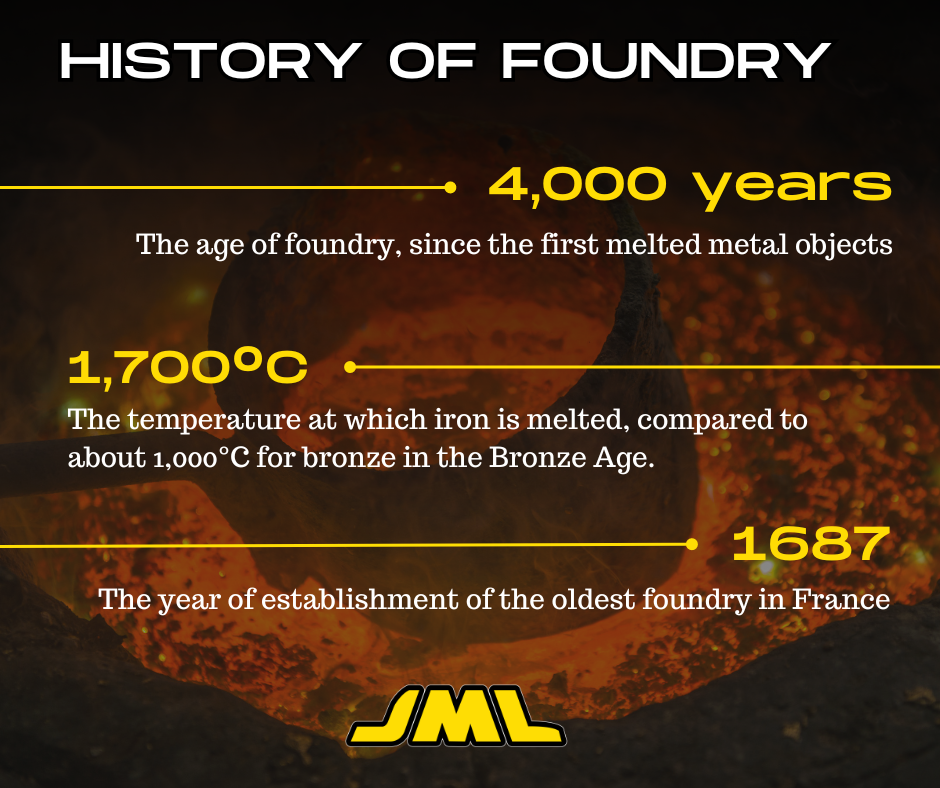

The origins of foundry date back to prehistoric times when our ancestors discovered the potential of fire to shape metals. The earliest foundries were rudimentary: pits dug in the ground, fueled by charcoal, where metals were melted and molded. This technique then refined over millennia, with the introduction of clay furnaces and the use of stone, and then metal molds.

🪙The Bronze and Iron Age

The Bronze Age (around 3000 BC) marks a key step, with the alloy of copper and tin to produce bronze, a more resistant and versatile material. Later, the Iron Age introduced an even stronger material, paving the way for new applications and technologies.

💥The Industrial Revolution: A Major Turning Point

The 18th century Industrial Revolution was a catalyst for the foundry industry. The invention of the steam engine and the development of mass production techniques allowed the production of metal parts in large quantities and with increased precision. Foundries transformed into industrial facilities, with high-performance furnaces and sophisticated molding techniques.

🌐Today: The Era of Technology and Environment

Today, foundries are at the forefront of technology. At JML Industrie, we work on several fronts:

✅ Green Sand Preparation: Advanced systems allow for the preparation of foundry sand with unmatched precision and efficiency, ensuring the quality and finish of the molded parts.

✅ Core Making Equipment: These machines produce complex cores with high precision, enabling the creation of parts with varied and detailed shapes.

✅ Vibrating Machines: They play a major role in the processing and transportation of materials in foundries, increasing productivity and reducing costs.

✅ Environmental Solutions: In a world where sustainability is essential, we develop solutions to minimize the environmental impact of foundries, such as reducing emissions and waste management.

Foundry, from its beginnings around a simple campfire 🔥to today’s high-tech industry, is a testimony to human ingenuity. At JML Industrie, we are proud to be part of this story, contributing to the continuous progress of this essential industry.