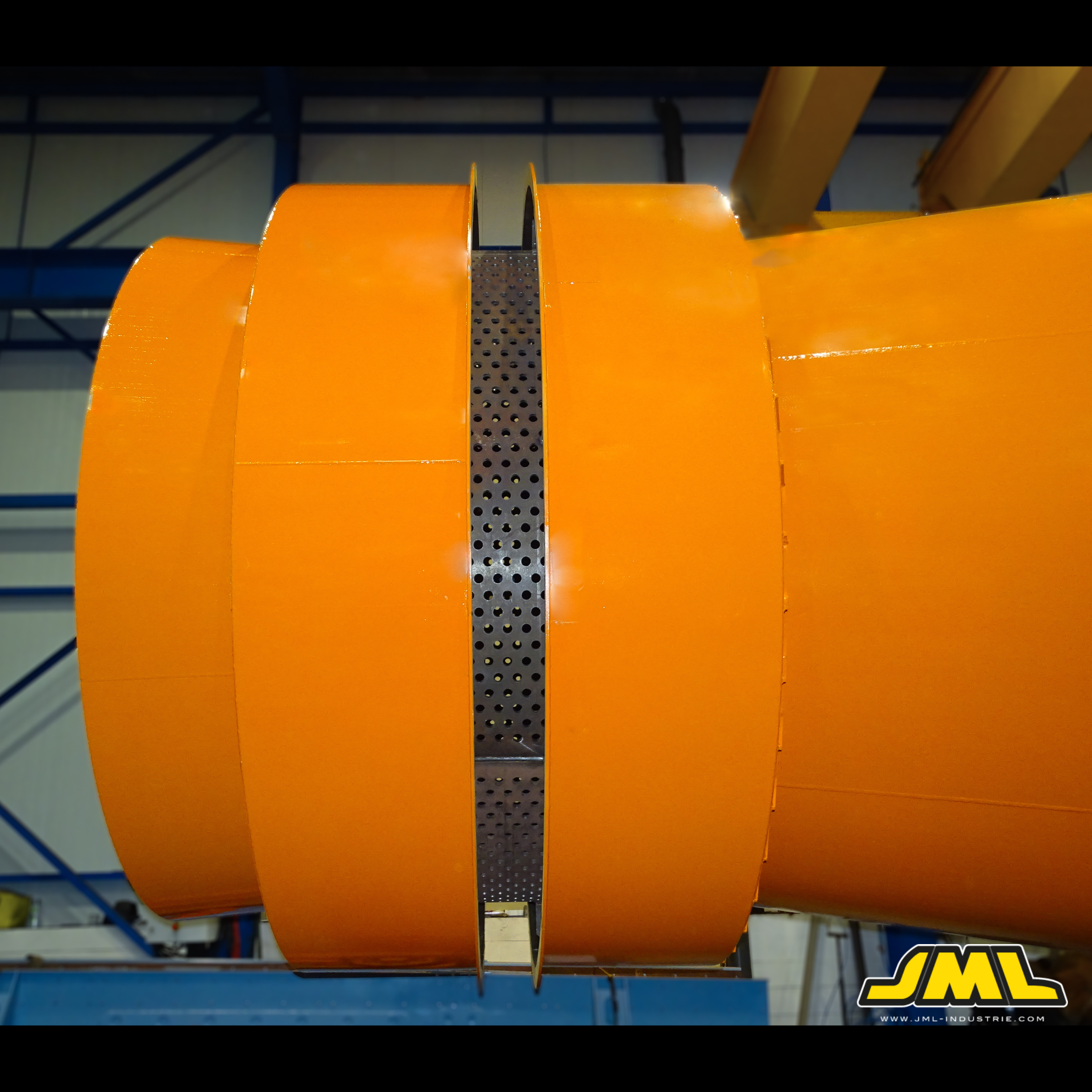

JML is currently manufacturing a cooling drum at his headquater and main production site located in France, Vrigne-au-bois (Grand Est).

This equipment is built to shake-out and to cool the sand and will be used by a foundry based in the East of France which produces ductile iron with vertical molding line to optimize their road plate production

JML has already installed 6 of them in the last 2 decades

Around 6 months are necessary to deliver this equipment as we are now at step 1 (workshop test to ensure all mechanical parts are well assembled).

Then step 2 will focus on commissioning on customer site

- empty test in line with the sand shop

- test with cold sand during 3 days

- after 2 weeks of production, optimisation with hot sand

We will be proud to share the second step with you next time !

We help your foundry stay ahead by helping you optimise your operations through the right machinery that gives you better results, reduced maintenance and reliable run times.